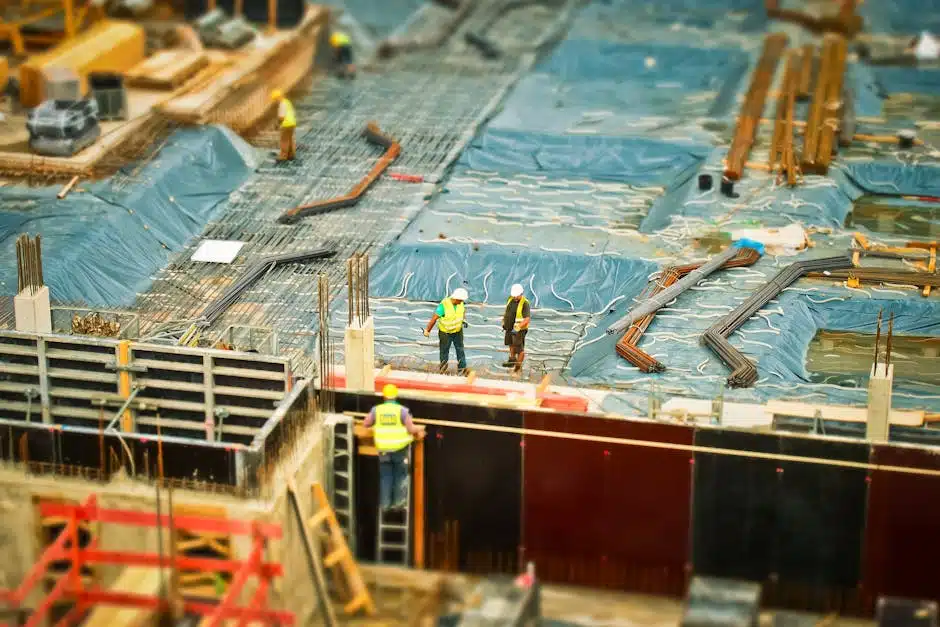

Embark on a journey delving into the world of structural repair contractors, where expertise meets innovation to tackle complex construction challenges head-on. From defining their pivotal role to exploring cutting-edge repair techniques, this guide promises to be an enlightening exploration of a crucial aspect of the construction industry.

Unveiling the intricacies and significance of structural repair contractors, this guide aims to shed light on their indispensable contributions to the realm of construction.

Overview of Structural Repair Contractors

Structural repair contractors play a crucial role in construction projects by specializing in fixing various structural issues that may arise in buildings or other structures. These professionals are equipped with the knowledge and expertise needed to assess, diagnose, and repair a wide range of structural problems.

It is essential to hire specialized contractors for structural repair work to ensure that the repairs are done correctly and safely. Unlike general contractors, structural repair contractors have specific training and experience in dealing with complex structural issues, making them better equipped to handle such tasks.

Common Structural Issues Requiring Contractor Expertise

- Foundation Settlement: When a building’s foundation sinks or shifts, causing structural instability.

- Cracks in Walls or Floors: Signs of underlying structural issues that need to be addressed promptly.

- Bowing Walls: Indicates pressure from the outside or foundation movement, requiring professional repair.

- Sagging Roof: Structural issues in the roof framing or supports that need to be corrected to prevent further damage.

Qualifications and Skills

To become a successful structural repair contractor, individuals need to possess specific qualifications and skills that are essential for excelling in this field.

Qualifications Needed

- A bachelor’s degree in civil engineering, construction management, or a related field is typically required to become a structural repair contractor.

- Obtaining a state-issued license is essential to legally operate as a contractor in most regions.

- Strong knowledge of building codes, regulations, and safety protocols is crucial for ensuring compliance and quality work.

Skills Required

- Excellent problem-solving skills to identify structural issues and develop effective repair solutions.

- Strong attention to detail to ensure accuracy in assessing damages and executing repairs.

- Effective communication skills to interact with clients, subcontractors, and other stakeholders throughout the repair process.

- Physical stamina and dexterity to handle the labor-intensive aspects of structural repair work.

Training and Certifications

- Many aspiring structural repair contractors undergo apprenticeships or on-the-job training to gain practical experience in the field.

- Seeking certifications from organizations such as the National Center for Construction Education and Research (NCCER) can enhance credibility and expertise.

- Continuing education courses on new technologies and techniques in structural repair are valuable for staying current in the industry.

Structural Repair Techniques

When it comes to structural repair techniques, contractors utilize a variety of methods to fix different types of damage. Before initiating any repairs, a thorough assessment of the structural damage is crucial to determine the best course of action. Let’s explore some of the innovative repair methods used in the industry.

Carbon Fiber Reinforcement

Carbon fiber reinforcement is a popular technique used to strengthen and repair concrete structures. Strips of carbon fiber are applied to the damaged area and bonded with epoxy resin. This method is known for its high tensile strength and durability, making it ideal for repairing cracks and reinforcing beams.

Polyurethane Injection

Polyurethane injection is commonly used to repair foundation cracks and leaks. A polyurethane resin is injected into the cracks, where it expands to fill the void and create a waterproof seal. This technique is effective for stabilizing foundations and preventing water infiltration.

Steel Plate Bonding

Steel plate bonding involves attaching steel plates to damaged concrete structures using epoxy adhesive. This method is used to provide additional support to weakened or cracked areas, enhancing the load-bearing capacity of the structure. Steel plate bonding is often used in combination with other repair techniques for comprehensive structural reinforcement.

Fiber Reinforced Polymers (FRP)

Fiber reinforced polymers, such as fiberglass and carbon fiber composites, are used to repair and strengthen concrete, masonry, and steel structures. These materials offer high strength-to-weight ratios and corrosion resistance, making them ideal for structural repair applications. FRP systems are versatile and can be customized to suit the specific needs of each project.

Safety Measures and Regulations

When it comes to structural repair work, safety is paramount to ensure the well-being of both workers and occupants of the building. Structural repair contractors must adhere to strict safety protocols on job sites to prevent accidents and injuries.

Safety Protocols

- Wearing appropriate personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and steel-toed boots.

- Implementing fall protection measures, especially when working at heights.

- Ensuring proper scaffolding and ladder safety practices are followed.

- Regular inspection of tools and equipment to ensure they are in good working condition.

Regulatory Standards

- Structural repair work is governed by regulatory standards set by organizations such as OSHA (Occupational Safety and Health Administration) in the United States.

- These standards Artikel specific safety requirements that contractors must follow to maintain a safe working environment.

- Non-compliance with these regulations can result in fines, penalties, or even legal action.

Importance of Compliance

Compliance with safety regulations in the structural repair industry is crucial to prevent accidents, injuries, and even fatalities. It not only protects the workers but also ensures the integrity of the repair work being performed.

Cost Estimation and Project Management

When it comes to structural repair projects, cost estimation and effective project management are crucial aspects that can determine the success of a job. In this section, we will delve into how structural repair contractors estimate costs, the key elements of project management for such jobs, and provide tips for effective budgeting and resource allocation.

Cost Estimation for Repair Projects

Cost estimation for structural repair projects involves a comprehensive analysis of various factors to provide an accurate budget for the job. Some key elements that contractors consider include:

- Assessment of structural damage and extent of repairs needed

- Cost of materials, equipment, and labor

- Permit fees and regulatory compliance costs

- Contingency funds for unexpected issues or additional repairs

Project Management for Structural Repair Jobs

Project management in structural repair jobs requires careful planning, coordination, and monitoring to ensure the project stays on track and within budget. Some essential elements of project management for such jobs include:

- Developing a detailed project plan outlining tasks, timelines, and milestones

- Assigning roles and responsibilities to team members

- Monitoring progress and addressing any issues promptly

- Regular communication with clients to provide updates and address concerns

Tips for Effective Budgeting and Resource Allocation

Effective budgeting and resource allocation are key to the success of structural repair projects. Here are some tips to ensure efficient management of resources:

- Conduct thorough research and analysis before creating a budget

- Allocate resources based on project priorities and critical path activities

- Regularly review and adjust the budget as needed to accommodate changes or unforeseen circumstances

- Communicate openly with the project team and stakeholders to ensure transparency and alignment

Closing Notes

In conclusion, structural repair contractors play a vital role in ensuring the integrity and safety of buildings. Their expertise, coupled with adherence to safety regulations, paves the way for sturdy and durable structures that stand the test of time. As you navigate the world of construction, remember the pivotal role these professionals play in upholding the structural integrity of buildings, making them a cornerstone of the industry.

Questions Often Asked

What qualifications are needed to become a structural repair contractor?

To become a structural repair contractor, individuals typically need a relevant degree in civil engineering or construction management, along with certifications in structural repair techniques.

How do structural repair contractors estimate costs for repair projects?

Contractors assess factors like the extent of damage, materials needed, labor costs, and project timeline to provide accurate cost estimates for repair projects.

What safety protocols must structural repair contractors follow on job sites?

Structural repair contractors are required to adhere to safety measures such as wearing protective gear, securing work areas, and following OSHA guidelines to ensure workplace safety.